Sinter is the "food" for ironmaking. Unstable quality directly reduces blast furnace capacity and profitability. However, domestic sintering plants have long been stuck with the same problem: ingredient testing relies on manual lab analysis, which takes 4 hours to get results. By the time the control room detects a significant alkalinity fluctuation, large quantities of substandard sinter have already been produced. Compounded by the interference of return fines, alkalinity adjustments often "overshoot", making it difficult to improve stability rates, which has become a major obstacle in building intelligent sintering plants.

DFMC's independently developed online sinter elemental analyzer completely breaks this "delayed response dilemma". It acts like a "Sintering Intelligence Hub" for the production process, "decoding" material composition in real time and coordinately adjusting ingredients, shifting the sintering process from "post-facto remediation" to "preemptive control."

Figure. Application at ANSTEEL

·Breakthrough Technology: Real-Time “Decoding” with Neutron Activation.

The analyzer’s game-changing capability stems from its use of advanced Prompt Gamma Neutron Activation Analysis (PGNAA) technology. Without any contact with the material on the belt, it rapidly scans and determines the content of key elements – including Ca, Si, Fe, Al, and Mg – as well as critical indicators like basicity and total iron (TFe). Results are generated instantly and synchronized to the control room, eliminating guesswork for operators. This allows for corrective action at the source, preventing off-spec sinter and over-adjustment, and laying a solid foundation for stable operation.

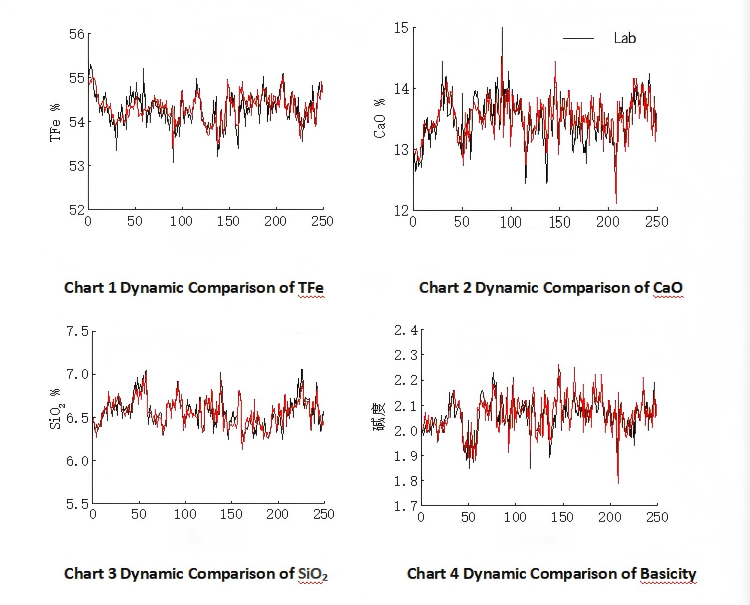

Deployed on a 360㎡ sintering machine at ANSTEEL, the analyzer provides real-time measurement of TFe, CaO, SiO₂, and basicity in the sinter mix. Charts 1 through 4 show a component comparison between the analyzer’s readings and laboratory results of the finished sinter.The data demonstrates outstanding performance in practice: the analyzer delivers highly accurate results, enabling reliable real-time monitoring of TFe, SiO₂, CaO, and basicity.

·Tangible Benefits: Stability Drives Substantial Annual Gains

In sintering field, stability equals profitability. The value of this "Sintering Intelligence Hub" is clearly illustrated by its performance at ANSTEEL: Before deployment, the basicity stability rate (within ±0.07) was just 84.33%. As the analyzer began to participate in the analysis and ore blending optimization process, the stability rate jumped to 88.31%, which led direct and significant financial impact: From the perspective of the sintering plant, stabilized basicity generates RMB 2.54 million in annual direct economic benefits. Furthermore, the improved consistency helps reduce the coke rate in the blast furnace, contributing an additional RMB 11+ million per year through increased production and coke savings.

·Proven Reliability: Industry Adoption Grows

The system’s robust long-term performance has not only led to additional orders from ANSTEEL but has also made it the technology of choice for major producers like JISCO, TIANZHU Group, and BINXIN STEEL Group, who have integrated it as a standard component of their operations. Its value extends far beyond real-time measurement: by enabling closed-loop automatic control of flux addition on the basis of online basicity data, it eliminates the traditional model of manual monitoring and delayed adjustment, which realizes a true intelligent workflow built on real-time detection, smart analysis, and precise control – driving gains in efficiency and product quality while reducing costs, and turning the vision of intelligent sintering into reality.

As the steel industry accelerates its intelligent transformation, sintering—a critical front-end process in ironmaking—will no longer tolerate inefficiency or delay. The Online Elemental Analyzer for Sintering is not merely an analytical instrument; it serves as an intelligent sintering control hub that enables steel plants to integrate key processes in smart production. With this system, achieving stable, precise, and cost-efficient sintering operation is no longer an insurmountable challenge. Moreover, it provides a reliable core engine for the construction of intelligent sintering plants.

Next page: Intelligent Mining and Selection Hard-core Technologies Energize the New Momentum of the Mining Industry: DFMC Appears at the 2025 Mining Frontier and Information Technology Intelligence Annual Confer