Ash content of clean coal is the most important index to indicate the quality of coal, and it is also one of the important indexes to assess the quality of coal plant products. At the same time, the ash content of commercial coal is an important basis for the settlement between coal plant and coal plant users. It is especially important to control the ash content of clean coal products accurately. It is an important guarantee to ensure the product quality, improve the yield of coal concentrate, reduce the consumption of medium, reduce the labor intensity of workers and improve the economic benefits of coal processing plant.

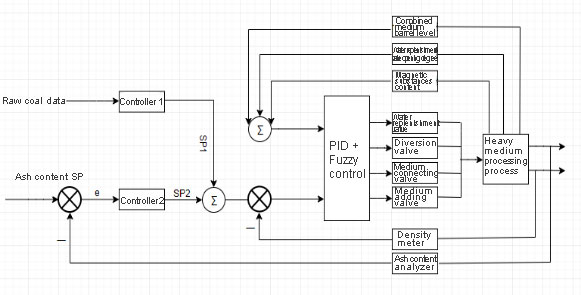

The intelligent control system of DFMC is based on the coal quality judgment model of the automatic coal quality identification system and the optimized setting model of the heavy medium suspension density. The system realizes intelligent setting of the suspension density value by collecting the ash data of raw coal and clean coal and using the advanced process control algorithm. It can analyze the mutual coupling relationship between variables such as magnetic matter content, coal sludge content, combined medium barrel level and water replenishment valve opening degree. It then establish a prediction model of the diversion valve opening degree to achieve automatic water replenishment, automatic diversion and automatic medium adding, eventually improving the processing effect, ensuring the product quality, improving the recovery rate of clean coal and reducing labor strength.

1.Grasp the quality index of heavy-medium clean coal timely

The coal quality of heavy-medium clean coal product is tested by PGNA analyzer, which gets rid of weaknesses of traditional sampling which sample preparation and assaying brings huge lag. The online analyzer can realize timely feedback on clean coal product quality, and provide timely and reliable control basis for intelligent control module.

2.Calibrate target density value precisely and quickly

The target density value is automatically analyzed and calculated by the intelligent calculation module based on raw coal quality, ash content of clean coal products and other data, it is no longer decided by operators according to their personal experience and subjective judgment. Accurate and efficient calibration can be achieved.

3.Precise control on density

The control of density takes the density output from the intelligent calculation module as control target. It realizes accurate control of processing density through PID control combined with fuzzy control.

The control logic diagram of the intelligent module is shown below:

The intelligent heavy medium coal processing process control system can realize precise control of the density and the ash content of clean coal.

The density can be steadily controlled within ±0.01g/L around target value.

The ash content can be steadily controlled within ±0.5% around target value.

The theoretical clean coal output can be increased by 0.5%-1.0%.

The system has applied at Sha Qu coking coal processing plant, China Coal Hua Jin.

The upper computer uses GE's ifix configuration software, the lower computer uses Rockwell's ContrrolLogix system, and the controller uses 1756-L73 large controller.

The ash control target is set at 11.10%, and the intercepted control curve for 6 consecutive hours is shown below: