Contact

Intelligent Instruments

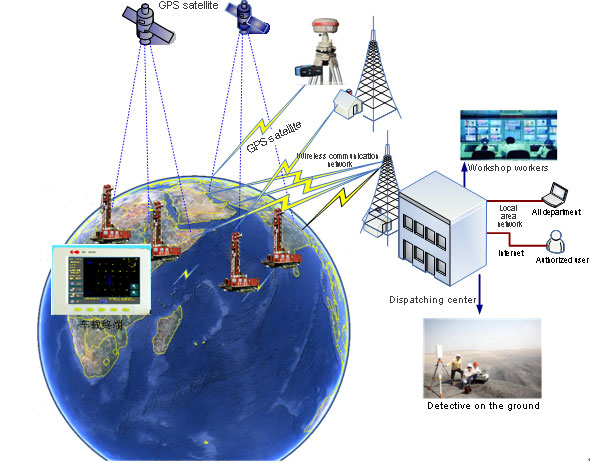

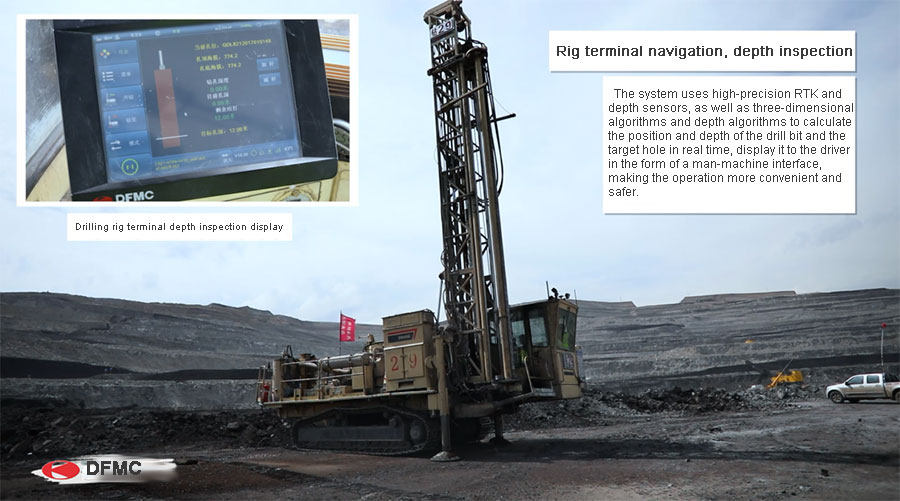

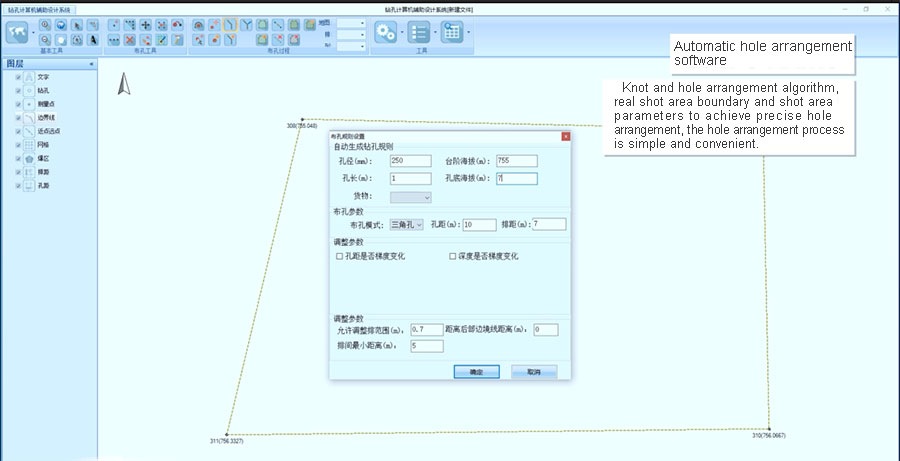

Intelligent Systems

Intelligent Solutions

Elemental Analysis and Grade Testing

Particle Size Detection

Density Detection

Ash and GCV Detection

Moisture Detection

Level Detection

Others

For Building Materials

For Mines and Mineral Processing

For Coal Processing